FAQ

Most frequent questions and answers

A spray dryer is a process unit operation used to separate solid from liquid feed using spraying process. Liquid or slurry feed get converts into dry powder or granules through atomization and evaporation. It finds applications in food processing, pharmaceuticals, chemicals, and more.

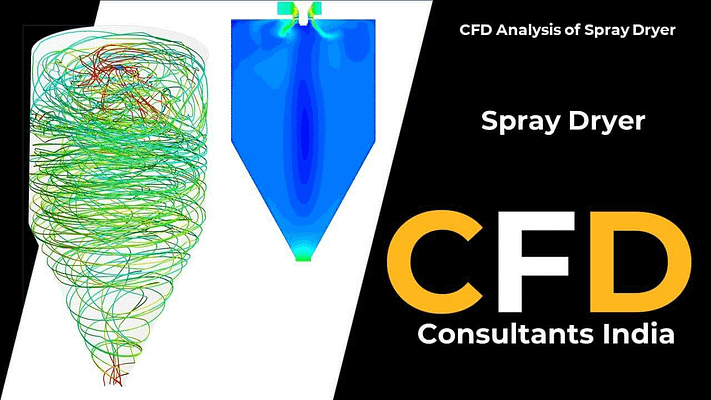

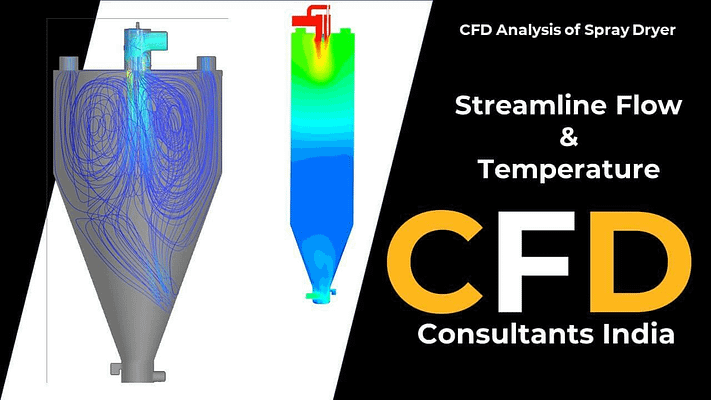

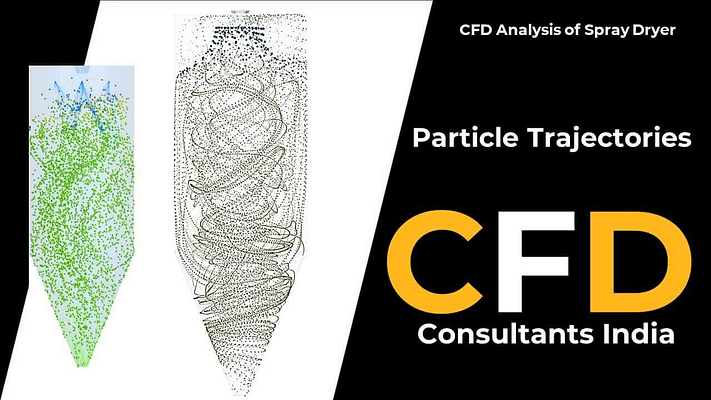

CFD analysis is crucial for optimizing spray dryer designs, predicting flow distribution of hot air, sprayed droplet trajectories, drying performance, and understanding fluid dynamics and heat transfer within the drying chamber.

Spray dryer primarily used to produce fine powder products widely used in industries such as food, pharmaceuticals, ceramics, and chemicals for processes like powder production, encapsulation, and agglomeration.

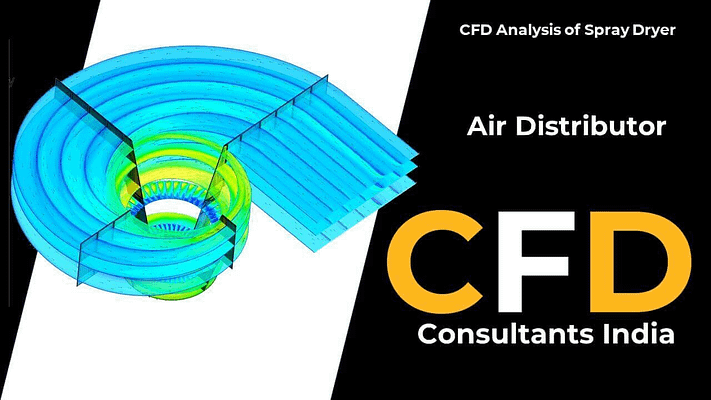

Hot air flow distributor, nozzle placement and angle of ejection, drying chamber and cyclone separator are the vital for effective CFD analysis and process optimization.

CFD simulations help engineers optimize spray dryer parameters, such as inlet conditions, droplet trajectories, temperature profiles, and product yield, resulting in enhanced efficiency.