FAQ

Most frequent questions and answers

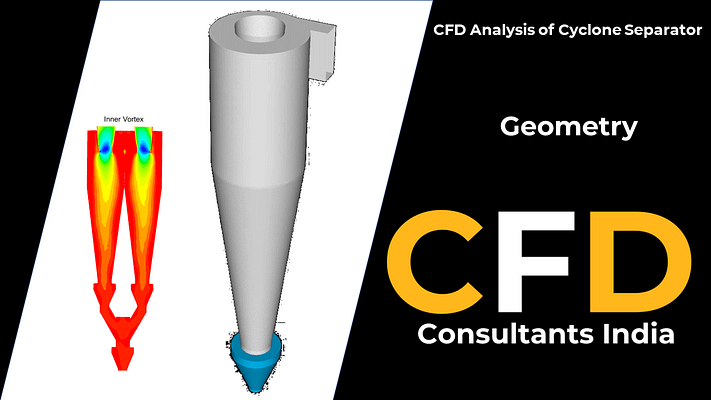

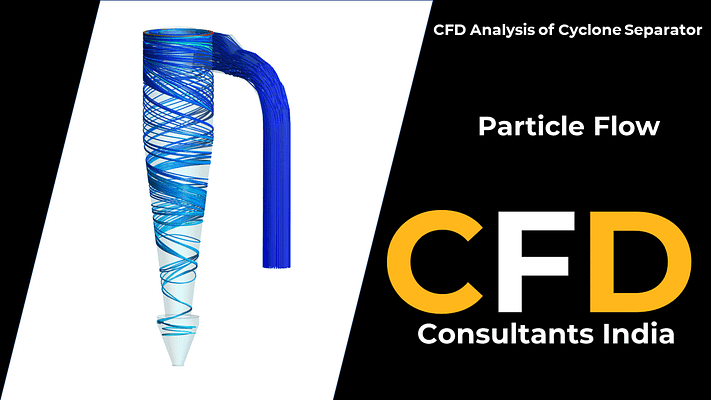

A cyclone separator is a device used to remove particulate matter or solid particles from gas or liquid streams.

It operates on the principles of centrifugal force and gravity. The greater the difference in density between the fluid and particles, the more effectively the particles are separated.

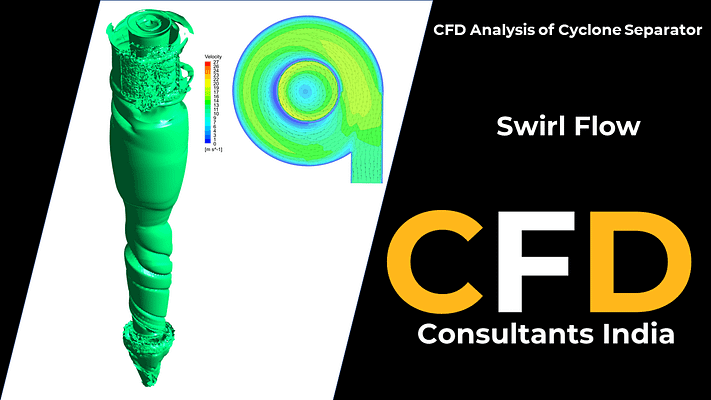

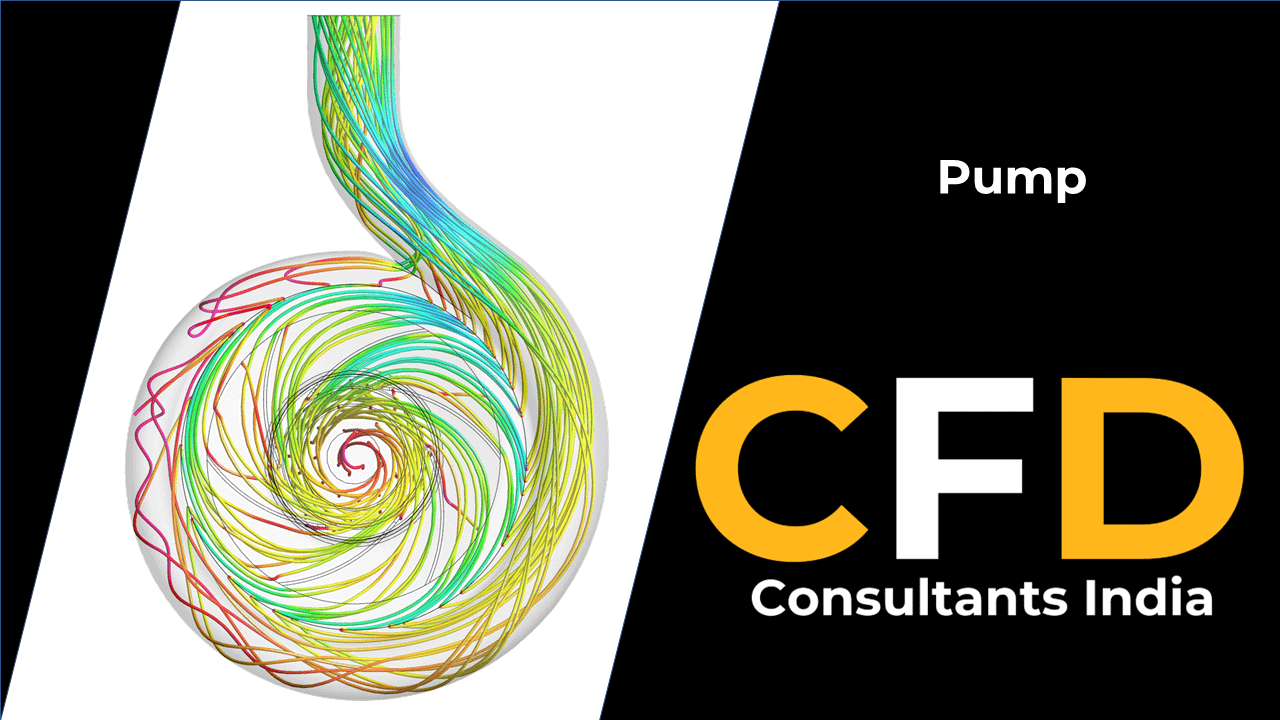

CFD analysis plays a crucial role in optimizing cyclone separator designs, predicting performance, and understanding particle behavior within the device.

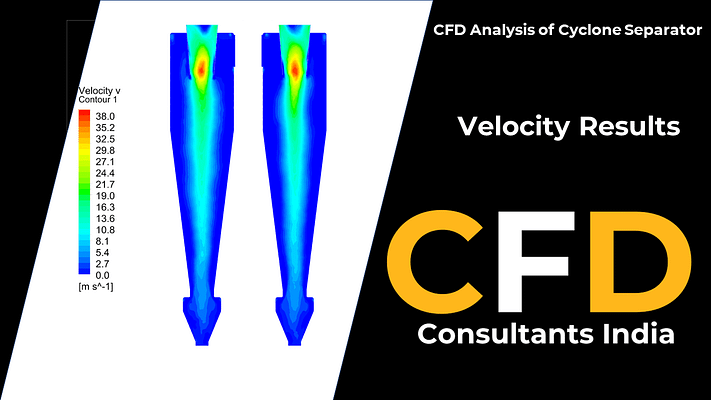

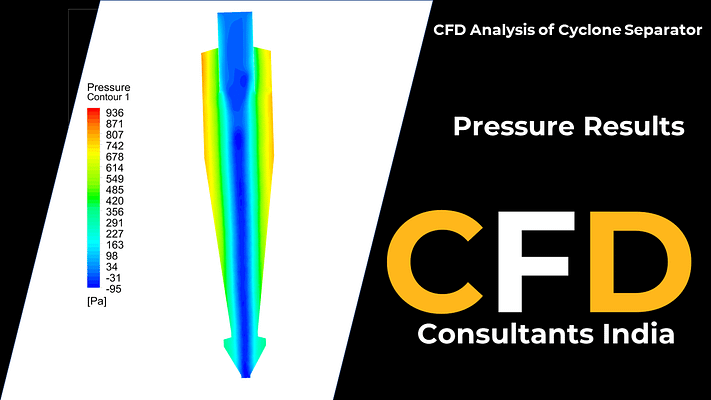

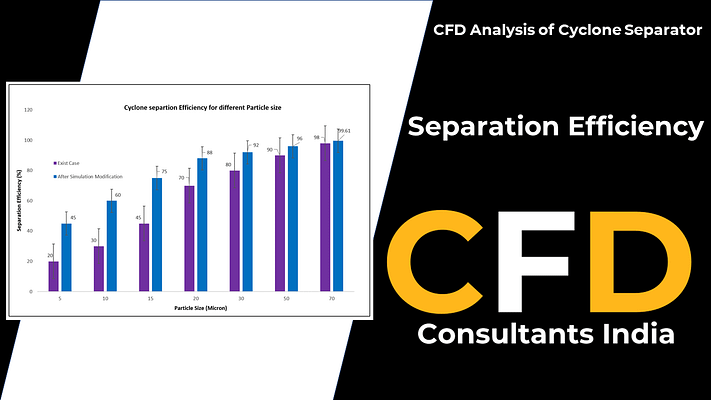

CFD simulations help engineers optimize cyclone separator geometries, predict separation efficiency, and evaluate pressure drops, ultimately leading to more efficient designs.

Challenges may include selecting appropriate turbulence models, handling multiphase flows, and ensuring accurate particle properties for simulations.

Computational effort increases with the use of more complex turbulence models, but in return, it provides highly accurate results for pressure drop and particle separation efficiency.

- k-e

- k-w

- k-w SST

- RSM

Based on our experience, a combination of 5-7 inflation layers on the wall in conjunction with the SST k-omega turbulence model has proven to be the best practice for cyclone separators of various types.