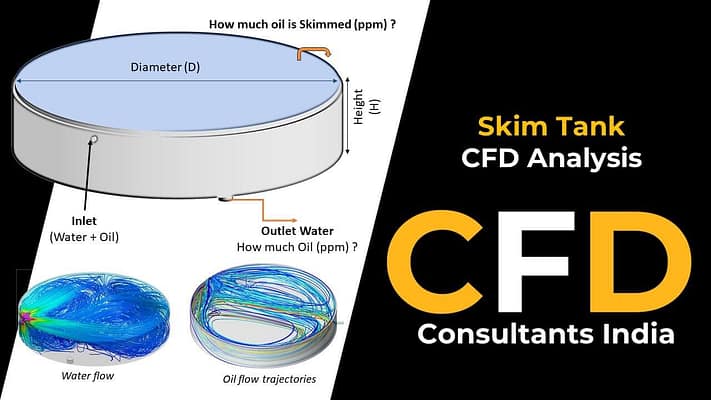

CFD Analysis of Skim Tank

Introduction

Skim tanks are widely used in various industries for the removal of oils and fats from water. Separation is based on the difference between the specific gravity of oil and water. When the retention time is sufficient, oil floats to the surface and can be separated by an overflow. This technique is only suitable for removing dispersed oil with a sufficiently large particle size.

The efficiency of the separation process depends on the design of the tank, flow behavior within tank, flow rate of the incoming water, and the properties of the contaminants. Computational Fluid Dynamics (CFD) is a useful tool to optimize the design of skim tanks and improve their performance. This case study explores the application of Computational Fluid Dynamics (CFD) analysis to optimize the design and performance of a skim tank.

The efficiency of the separation process depends on the design of the tank, flow behavior within tank, flow rate of the incoming water, and the properties of the contaminants. Computational Fluid Dynamics (CFD) is a useful tool to optimize the design of skim tanks and improve their performance. This case study explores the application of Computational Fluid Dynamics (CFD) analysis to optimize the design and performance of a skim tank.

Methodology

The Skim Tank is modeled with all geometry details including inlets and outlets for water and oil. The simulation is set up to solve the Reynolds-averaged Navier-Stokes (RANS) equations for turbulent flow along with Eulerian method to track the water flow behavior and Lagrangian multiphase method is used to track oil droplets. This assumption suits best since volume of oil is far less than water.

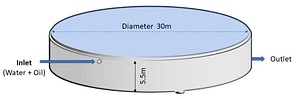

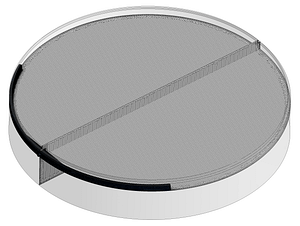

Geometry and Meshing

A detailed 3D model of the existing skim tank geometry was created.

The model was meshed to discretize the fluid domain, ensuring accuracy in capturing the flow phenomena.

CFD Simulation

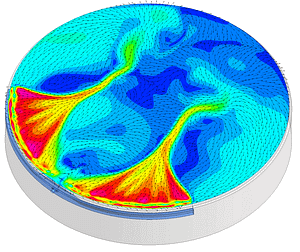

Real-world operating conditions, including flow rates and temperatures, were incorporated into the simulation. The inlet and outlet conditions were set to mimic the actual operating environment. The simulation was run using industry-standard CFD software to analyze fluid flow, turbulence, and particle trajectories within the skim tank. Multiple scenarios were simulated to assess the impact of design modifications on separation efficiency.

![]()

Results and Conclusion

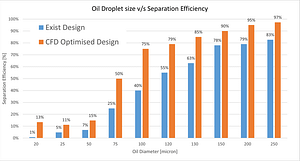

The simulation identified a flow bypass issue in the skim tank’s inlet and outlet configurations, causing immediate oil flushing and hindering proper separation time. A proposed modification, optimizing these designs, substantially improved separation efficiency from 65% to 92%. This underscores the critical role of simulation in pinpointing inefficiencies and guiding targeted design changes for enhanced industrial processes.

In conclusion, CFD analysis proved to be a valuable tool in optimizing the skim tank design, providing actionable insights that led to tangible improvements in separation efficiency. The successful implementation of the recommended changes underscores the importance of leveraging advanced simulation techniques in the oil and gas industry to enhance operational performance.

Read out how CFD analysis improves the separation efficiency of cyclone separators. Learn how the study identifies flow patterns, particle trajectories, and proposes design modifications for enhanced performance.

Ensure the safety of occupants, compliance regulations with CFD analysis for fire and smoke ventilation systems in the event of fire & smoke.

Enhance the performance of your pumping system with CFD analysis of pump sump and pumping station. Discover how to improve flow uniformity, prevent vortex formation, and enhance pump efficiency for optimal operation.

Let's stay in touch!

To get recent updates, stay connect us on our LinkedIn page! Don’t hesitate to reach out to us for any questions, concerns or future collaborations

Contact Us

We are here to help! With just a quick input details we will be able to respond to your inquiry.

E-Mail: info(at)cfdconsultantsindia.com

CFD Consultants India a leading provider of CFD simulation consultation and services. We use finite volume computation technique to predict the flow behavior using various commercial CFD software’s. At CFD Consultants India, we understand the importance of accurate and reliable CFD simulations in the design and development process. With years of experience and expertise in the field, we offer customized solutions to meet your specific requirements and help you achieve your goals.

Whether you are looking to optimize your product design, improve performance, reduce costs, or enhance safety, CFD Consultants India can help. Contact us today to learn more about our services and how we can help you achieve your goals.

© Copyright CFD Consultants India 2023 | All rights reserved.