FAQ

Most frequent questions and answers

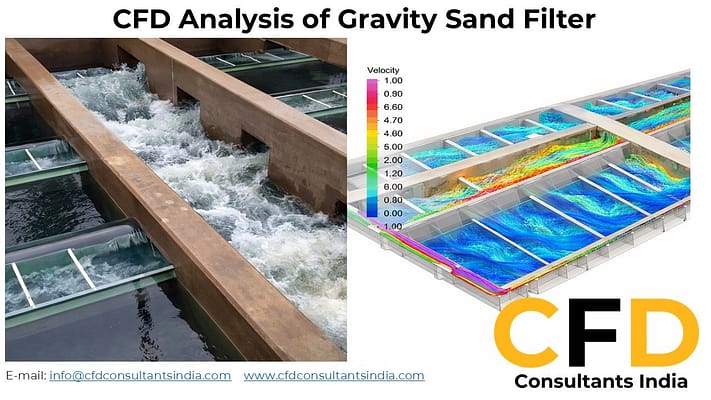

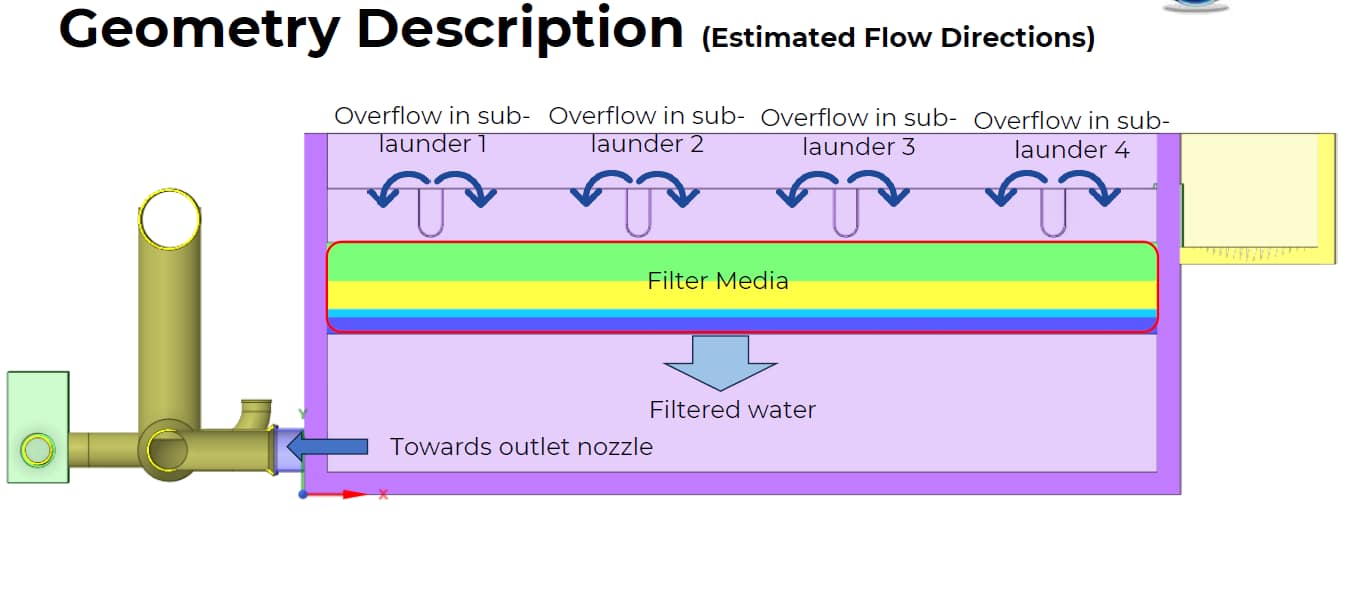

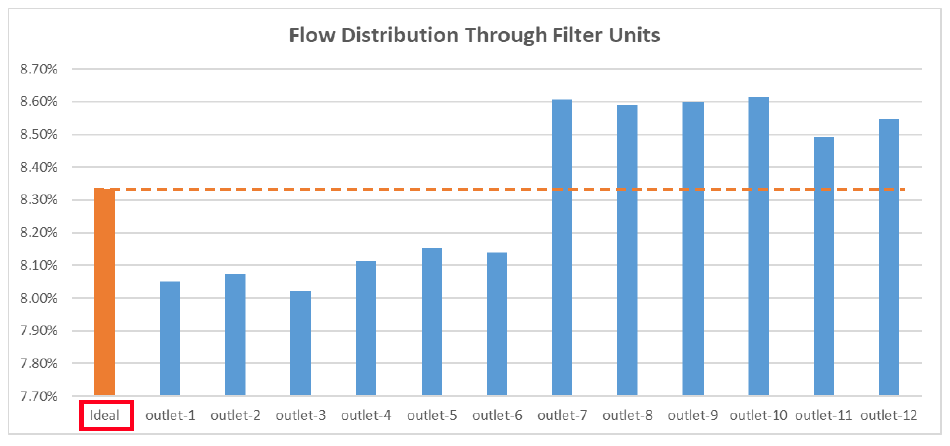

CFD analysis helps understand how water actually travels inside the gravity sand filter, revealing velocity distribution, pressure variation and potential channeling effects. This insight allows engineers to identify inefficiencies, improve flow uniformity and enhance overall filtration performance before making physical design changes.

CFD can identify short-circuiting of flow, stagnant regions, non-uniform velocity areas, excessive pressure drop and inefficient utilization of the filtration media. Detecting these issues early helps improve design and operational reliability.

Yes. By studying the internal flow pattern, CFD helps redesign inlet distribution, optimize internal arrangements and enhance flow uniformity across the media bed. This leads to better media utilization, improved filtration efficiency and longer system stability.

Water treatment plant designers, EPC consultants, municipal treatment authorities, industrial water users and engineering teams responsible for filtration performance benefit greatly from CFD analysis of gravity sand filters.

Yes. CFD plays a very important role in evaluating backwash efficiency by showing how uniformly the sand bed expands and whether cleaning water distributes evenly. It helps identify dead zones, excessive uplift zones and backwash imbalance, enabling engineers to redesign the system for more effective media cleaning and longer filter life.