CFD Analysis of Chiller Yard

Introduction

A chiller yard is an essential component of many large commercial and industrial facilities, providing cooling by removing heat from a liquid, usually water, that is then circulated through cooling coils to cool air or equipment. The chiller yard typically consists of multiple chillers, cooling towers, and pumps working together to maintain the desired temperature. It is commonly used in HVAC systems for buildings, data centers, manufacturing facilities, and power plants.

Problem

Despite their crucial role, chiller yards often face challenges related to airflow and heat distribution. Inadequate ventilation or poor airflow can lead to hotspots, inefficient cooling, and increased energy consumption. Additionally, recirculation of hot exhaust air back into the system can exacerbate these issues. CFD simulation can be employed to identify and resolve these airflow problems, ensuring optimal performance and energy efficiency.

CFD Modeling

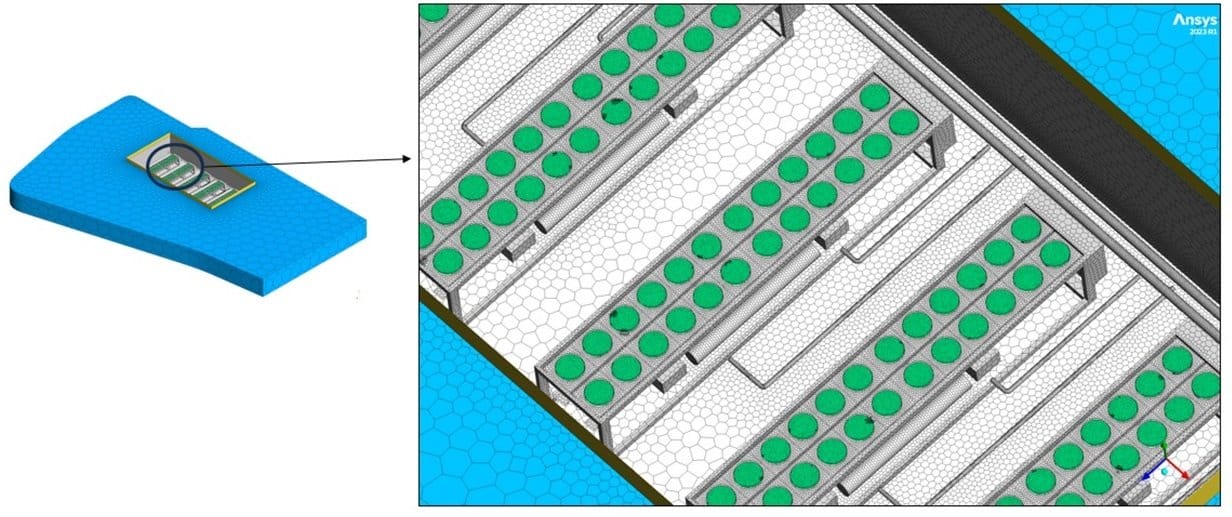

To analyze the airflow and temperature distribution in the chiller yard, a CFD simulation was conducted. The methodology involved creating a 3D model of the chiller yard, including all relevant components like chillers, cooling towers, and surrounding structures. Steady-state simulations were performed using the Reynolds-Averaged Navier-Stokes (RANS) equations with the k-ε turbulence model to predict airflow behavior.

Boundary conditions were set as follows:

- Inlets: Specified velocity corresponding to the cooling tower fan speed.

- Outlets: Pressure-outlet conditions to simulate the exhaust.

- Walls and Structures: No-slip condition to account for frictional effects.

Observation

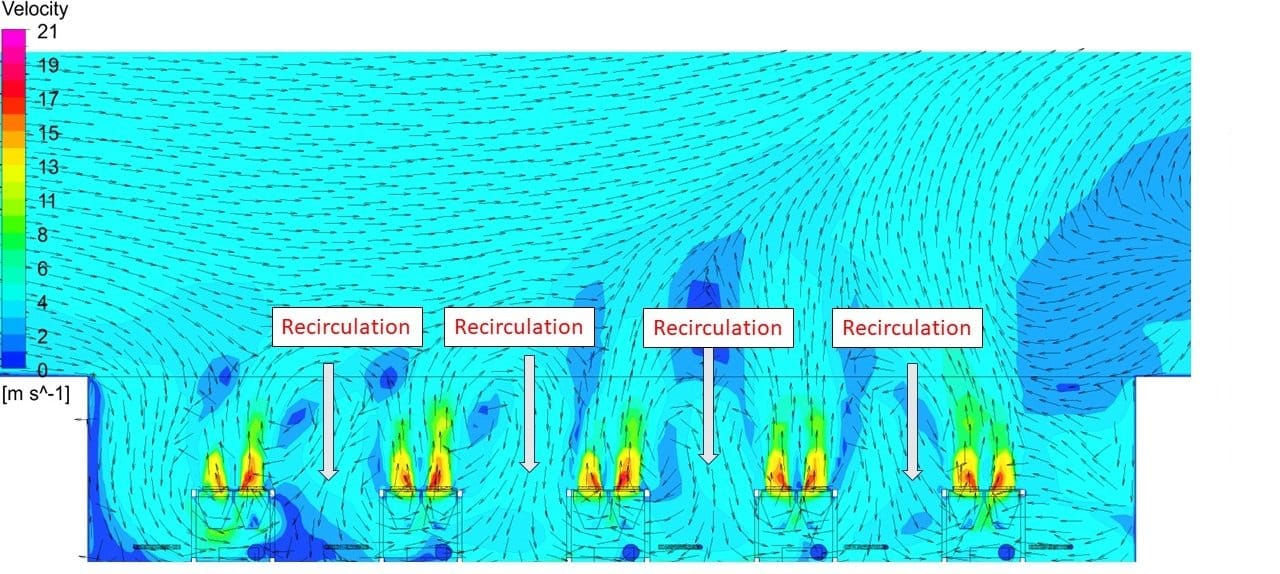

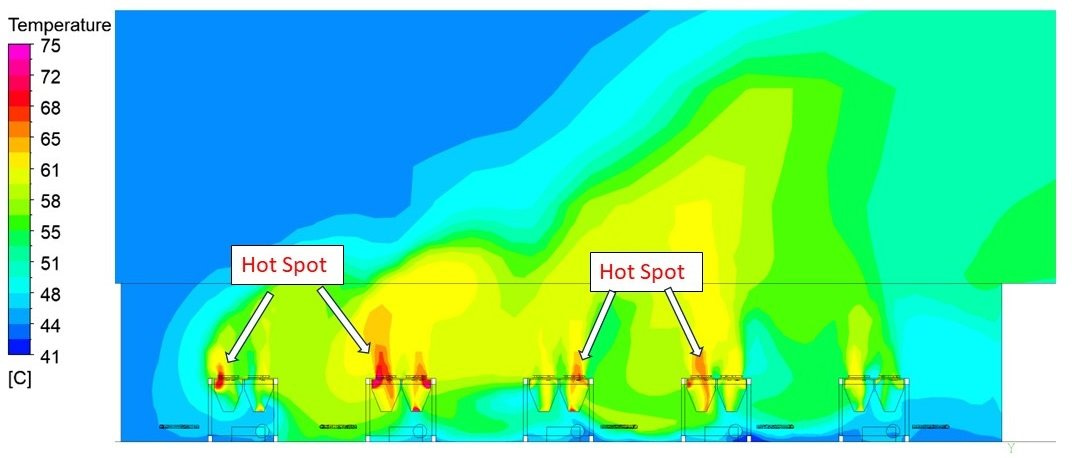

The CFD analysis revealed several critical issues:

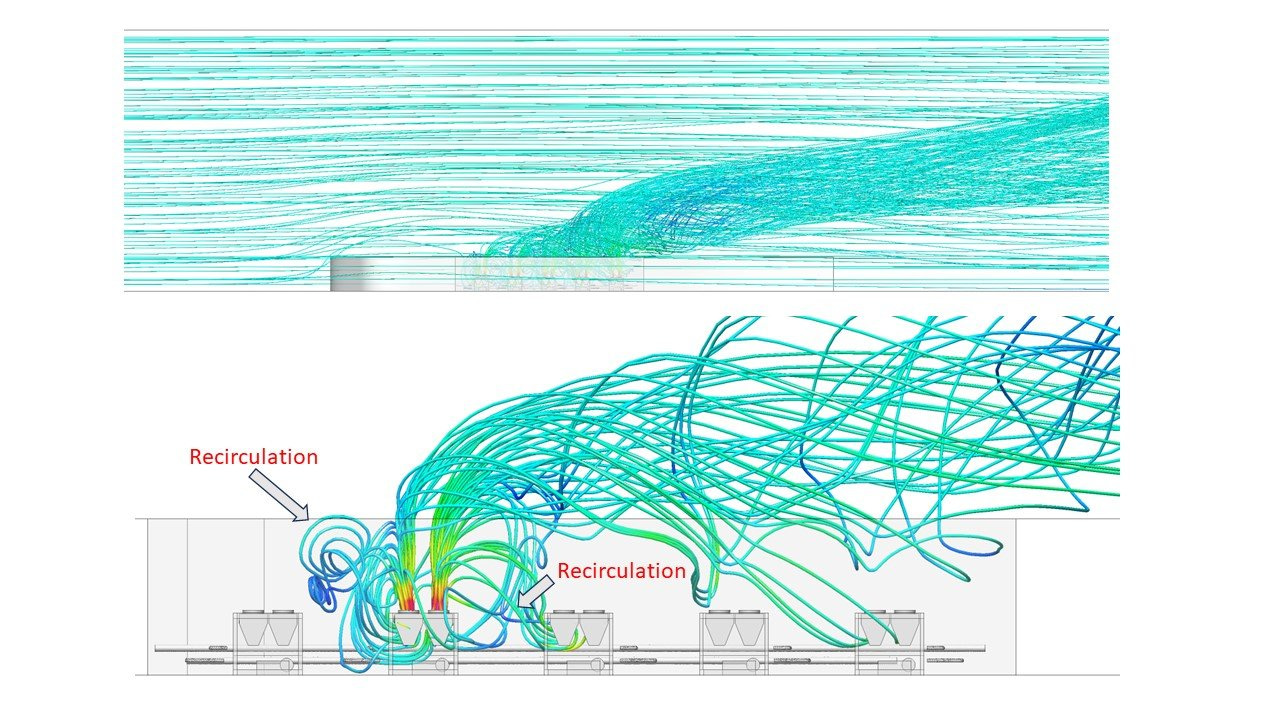

- Air Recirculation: Hot exhaust air from the cooling towers was observed recirculating back towards the air intakes, reducing cooling efficiency.

- Hotspots: Certain areas within the yard exhibited significantly higher temperatures, indicating poor airflow and potential overheating of equipment.

- Velocity Distribution: Uneven air distribution was detected, with some regions experiencing low airflow, leading to stagnant zones.

Numerical results indicated temperature variations of up to 20°C in different regions of the yard, which could lead to equipment malfunction if not addressed.

Recommendation

Based on the CFD analysis, several recommendations were provided to mitigate the identified issues:

- Repositioning of Cooling Towers: Moving the cooling towers further apart to minimize the risk of recirculation.

- Installation of Baffles: Installing baffles or barriers to direct airflow and prevent hot air from re-entering the intake zones.

- Enhanced Ventilation: Adding auxiliary fans in stagnant zones to improve airflow and reduce hotspots.

- Regular Monitoring: Implementing a monitoring system to continuously track temperature and airflow patterns, allowing for real-time adjustments.

These changes are expected to improve the overall efficiency of the chiller yard, reduce energy consumption, and prolong the lifespan of the equipment.

If you are facing similar challenges in your chiller yard or any other HVAC system, CFD simulation can provide invaluable insights and solutions. Reach out to us at info[at]cfdconsultantsindia.com for expert assistance in optimizing your cooling systems through advanced CFD analysis.

Read out how CFD analysis improves the separation efficiency of cyclone separators. Learn how the study identifies flow patterns, particle trajectories, and proposes design modifications for enhanced performance.

Ensure the safety of occupants, compliance regulations with CFD analysis for fire and smoke ventilation systems in the event of fire & smoke.

Enhance the performance of your pumping system with CFD analysis of pump sump and pumping station. Discover how to improve flow uniformity, prevent vortex formation, and enhance pump efficiency for optimal operation.

Let's stay in touch!

To get recent updates, stay connect us on our LinkedIn page! Don’t hesitate to reach out to us for any questions, concerns or future collaborations

Contact Us

We are here to help! With just a quick input details we will be able to respond to your inquiry.

E-Mail: info(at)cfdconsultantsindia.com

CFD Consultants India a leading provider of CFD simulation consultation and services. We use finite volume computation technique to predict the flow behavior using various commercial CFD software’s. At CFD Consultants India, we understand the importance of accurate and reliable CFD simulations in the design and development process. With years of experience and expertise in the field, we offer customized solutions to meet your specific requirements and help you achieve your goals.

Whether you are looking to optimize your product design, improve performance, reduce costs, or enhance safety, CFD Consultants India can help. Contact us today to learn more about our services and how we can help you achieve your goals.

© Copyright CFD Consultants India 2023 | All rights reserved.