Introduction

Pumps play a crucial role in various industries, ensuring the efficient transfer of fluids and maintaining the smooth operation of processes. However, understanding and improving pump performance can be challenging without a detailed analysis of the fluid flow behavior. In this case study, we explore CFD Analysis of Centrifugal Pump to optimize the performance of a pump, leading to improved efficiency, reduced energy consumption, and enhanced reliability.

Objective

The objective of this study was to analyze the fluid flow characteristics within a pump and identify areas for improvement to enhance its performance. By conducting a CFD analysis, we aimed to evaluate the pump’s hydraulic efficiency, identify potential flow instabilities, and optimize the design to achieve better performance.

Methodology

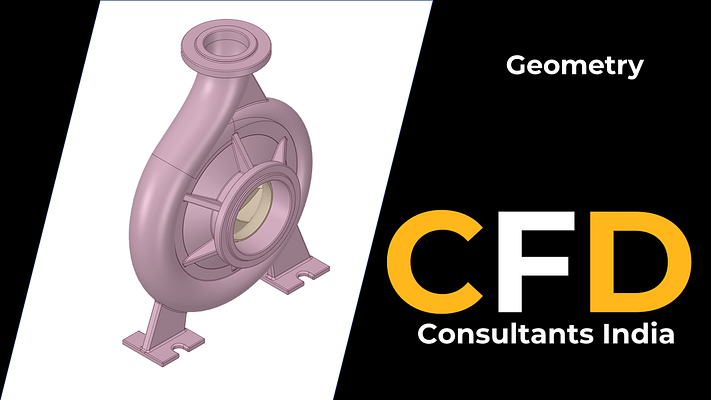

1. Geometry and Meshing

The three-dimensional geometry of the pump, including the impeller, volute, and casing, was created based on design specifications and CAD models. A high-quality mesh was generated, capturing the complex geometry and ensuring accurate representation of the fluid flow behavior. Special attention was given to resolving boundary layers and regions of flow separation.

2. Fluid Domain and Boundary Conditions

The fluid domain was defined to include the pump’s internal components, such as the impeller and volute. Appropriate boundary conditions, such as inlet velocity profiles and outlet pressure, were assigned to simulate realistic operating conditions. The fluid properties, such as density and viscosity, were specified based on the working fluid.

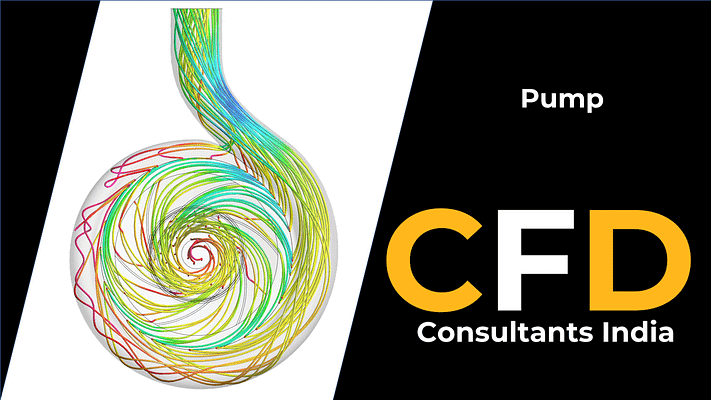

3. Fluid Flow Simulation

The CFD simulation employed the Reynolds-Averaged Navier-Stokes (RANS) equations to model the fluid flow and turbulence within the pump. The appropriate turbulence model, such as the k-omega SST model, was selected to capture the turbulence effects accurately.

4. Post-processing and Analysis

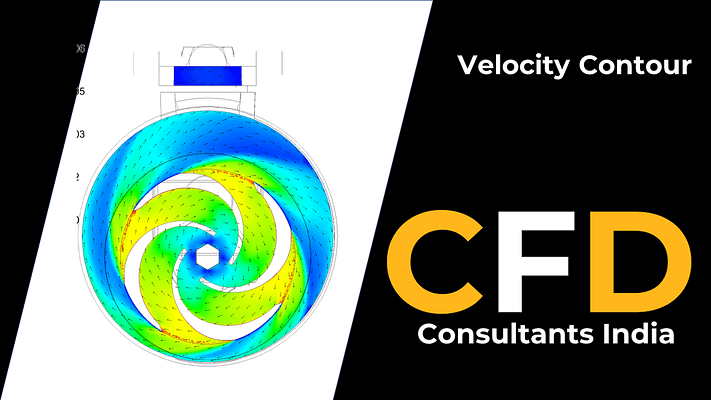

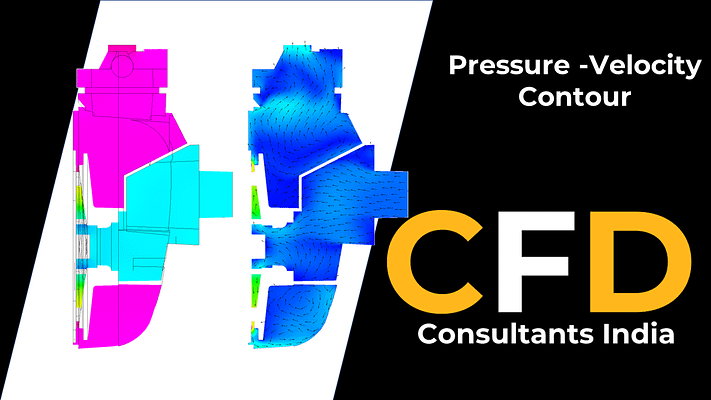

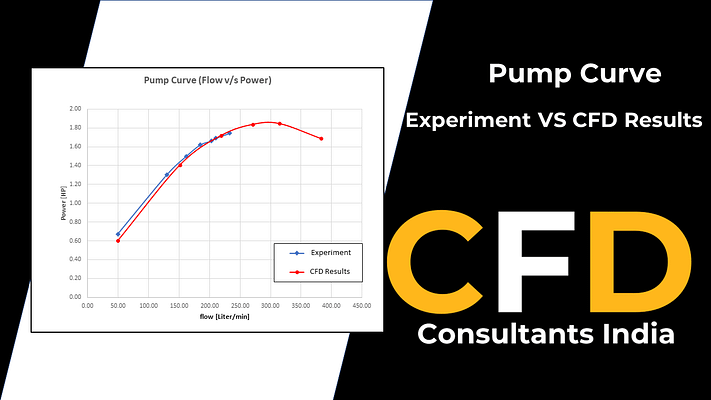

The simulation results were post-processed to analyze various performance parameters, including pressure distribution, velocity profiles, flow rate, and hydraulic efficiency. Key performance indicators, such as head-rise characteristics and efficiency curves, were plotted and analyzed to evaluate the pump’s performance.

Results and Conclusion

The CFD analysis provided valuable insights into the pump’s performance and highlighted areas for improvement. Key findings and conclusions from the study included:

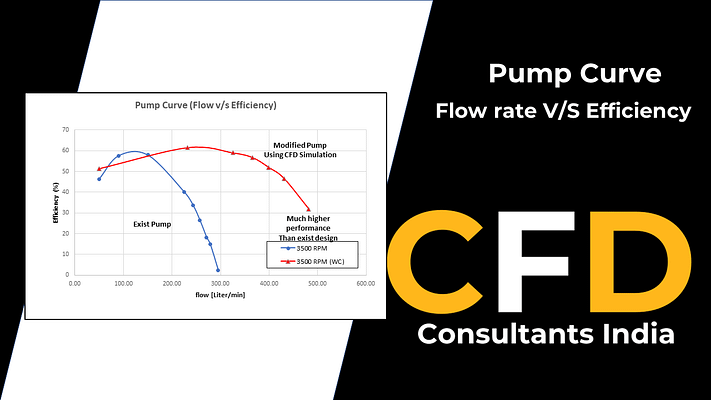

1. Efficiency analysis: The CFD analysis allowed the calculation of the pump’s hydraulic efficiency and provided a detailed understanding of its performance across different operating conditions. Inefficiencies, such as flow separation or recirculation, were identified and addressed through design modifications.

2. Flow optimization: By analyzing the velocity profiles and pressure distribution, the CFD analysis enabled the identification of flow instabilities and recirculation zones within the pump. These insights guided the optimization of impeller design, volute geometry, and other critical components to improve flow characteristics and minimize energy losses.

3. Performance validation: The CFD results were compared with experimental data or established industry standards to validate the accuracy of the simulation. This helped build confidence in the CFD model and the proposed design modifications.

By implementing the design modifications based on the CFD analysis, the pump’s performance was significantly enhanced. The optimized design resulted in improved hydraulic efficiency, reduced energy consumption, and enhanced reliability. This case study demonstrates the effectiveness of CFD analysis in optimizing pump performance and serves as a valuable tool for pump manufacturers and operators to achieve enhanced efficiency and cost savings. CFD