Introduction

Computational Fluid Dynamics (CFD) is a powerful tool used in engineering and scientific applications to analyze fluid flow, heat transfer, and other related phenomena. By leveraging mathematical modeling and numerical methods, CFD provides insights into complex fluid behavior, aiding in the design optimization and performance evaluation of various systems. In this blog, we will explore what CFD is and the fundamental steps involved in the CFD process.

What is CFD?

CFD, or Computational Fluid Dynamics, is a branch of fluid mechanics that utilizes numerical methods and computer simulations to study the behavior of fluids. It involves solving the governing equations of fluid flow and heat transfer using computational algorithms. By dividing the fluid domain into discrete elements or cells, CFD simulations allow for a detailed analysis of fluid behavior, including velocity distribution, pressure gradients, temperature distribution, turbulence effects, and more.

Steps Involved in CFD

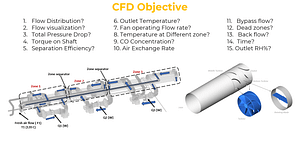

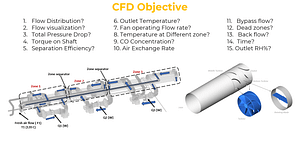

1. Problem Definition

The first step in any CFD analysis is to clearly define the problem. This includes identifying the objectives, understanding the fluid flow and boundary conditions, and specifying the geometry and domain of interest. Proper problem definition is crucial for setting up an accurate simulation. This is a critical aspect because it allows the CFD engineer to select the most appropriate CFD assumptions that align with real-world challenges, enabling timely delivery of results.

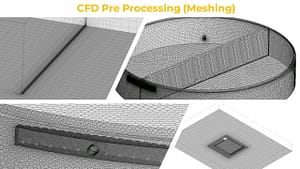

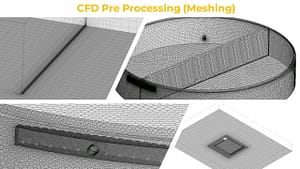

2. Pre processing (Geometry Cleaning & Meshing)

Once the problem is defined, the next step is preprocessing. This involves creating a computational grid or mesh, which discretizes the fluid domain into small elements or cells. The grid resolution plays a critical role in the accuracy and computational efficiency of the simulation. Other preprocessing tasks include specifying material properties, boundary conditions, and initial conditions.

3. Mathematical Modeling (Setting up BC)

Selecting appropriate boundary condition (BC) is also crucial part of pre processing. In this step, the mathematical model governing the fluid flow and heat transfer is defined as per the problem definition. This typically involves selecting the appropriate equations and boundary conditions value based on the characteristics of the problem, such as the Navier-Stokes equations for fluid flow or the energy equation for heat transfer. Various turbulence models may also be employed to account for turbulent flow behavior.

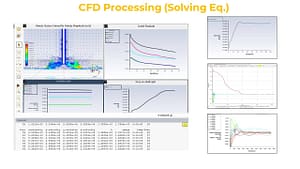

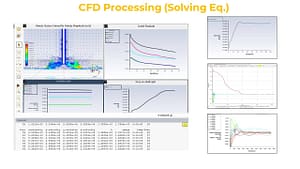

4. Numerical Solution (Run Solver)

With the problem set up and the mathematical model defined, the next step is to solve the equations numerically. This involves employing numerical algorithms and techniques to discretize and solve the equations iteratively. The solution is obtained by solving the equations at each cell in the grid, considering the boundary and initial conditions.

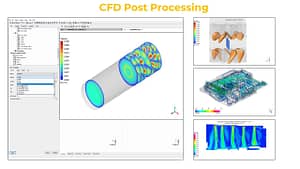

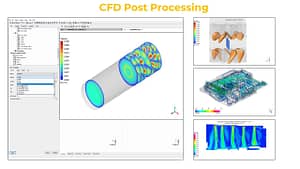

5. Postprocessing and Analysis

After obtaining the numerical solution, postprocessing and analysis are performed. This step involves visualizing and interpreting the results to gain valuable insights. Postprocessing tasks may include generating contour plots, velocity vectors, streamlines, and temperature distributions. Comparisons with experimental data or design specifications can be made to evaluate the performance of the system and make necessary improvements. I personally believe that this is the most critical step for a CFD engineer, as it requires a keen eye to identify results that are beneficial for further product development.

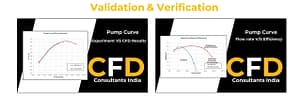

6. Validation and Verification

Validation and verification are essential steps to ensure the accuracy and reliability of the CFD simulations. Validation involves comparing the simulation results with experimental data or benchmark cases to verify the accuracy of the model and numerical approach. Verification focuses on assessing the convergence and numerical errors associated with the simulation.

In Contrast

Computational Fluid Dynamics (CFD) is a powerful tool that enables engineers and scientists to analyze and optimize fluid flow and heat transfer systems. By following the fundamental steps of problem definition, preprocessing, mathematical modeling, numerical solution, postprocessing, and validation, CFD simulations provide valuable insights for design optimization and performance evaluation. As technology continues to advance, CFD plays an increasingly important role in various industries, helping to improve efficiency, reduce costs, and enhance product performance.

Author : Mr. Manish Bhasme | LinkedIn