3 Phase Separator

3 Phase Separators are essential in the oil and gas industry, designed to separate crude oil into its three constituent phases: oil, water, and gas. The efficiency of this separation process is critical for optimizing downstream operations and ensuring smooth workflow. This blog explores how Computational Fluid Dynamics (CFD) technology is transforming the design and operation of three-phase separators, offering significant benefits to the industry.

1. What is a Three-Phase Separator?

A three-phase separator is vital equipment used to separate well fluids into gas, oil, and water. This separation is based on the different densities and behaviors of these phases:

Gas: Being the lightest, rises to the top due to its lower density.

Oil: Settles in the middle layer.

Water: Being the densest, sinks to the lowest point.

Effective separation is vital for ensuring that each phase is adequately processed and transported in the oil and gas production chain.

2. How CFD Enhances Three-Phase Separators ?

Computational Fluid Dynamics (CFD) is a powerful simulation tool used to model fluid flow and heat transfer within systems. In the context of three-phase separators, CFD provides several key advantages:

3. What are the Key Insights from CFD Analysis ?

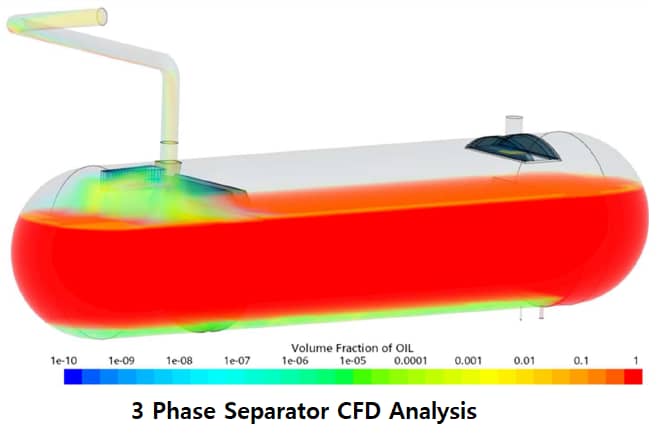

CFD helps in understanding how the fluid distribution within the separator affects separation. For instance, ensuring that gas rises quickly to the top while oil and water settle effectively can enhance performance.

Accurate simulation of the interfaces between gas, oil, and water is crucial. CFD models, such as the Volume of Fluid (VOF) method, provide precise interface tracking, ensuring minimal mixing and high separation quality.

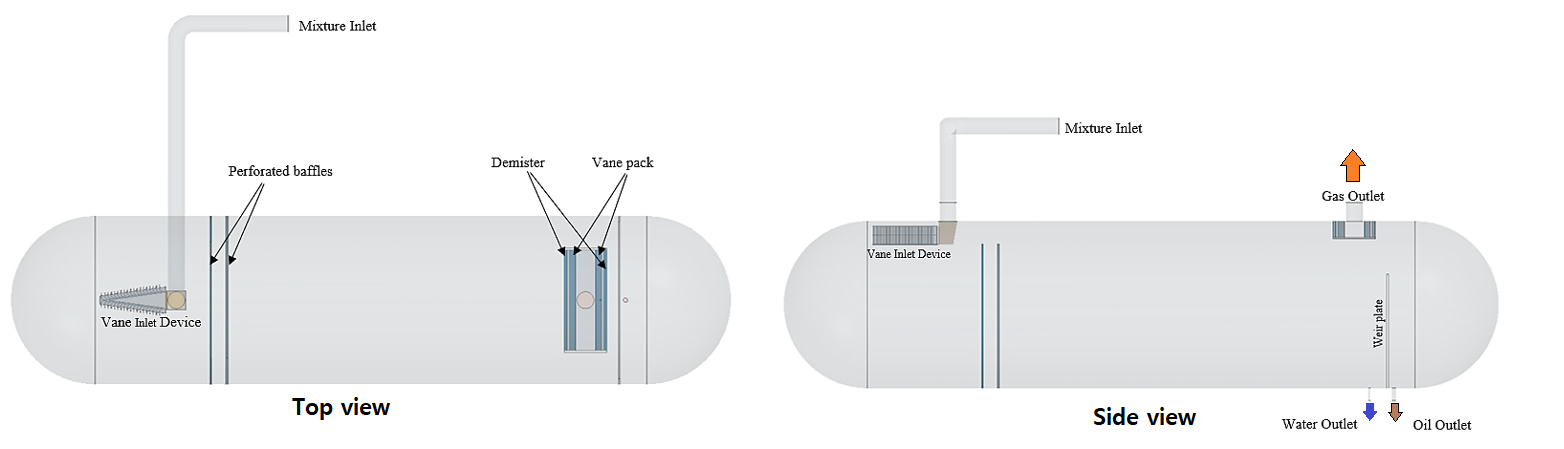

Modifying inlet designs to reduce turbulence, adjusting the height and placement of weir plates, and strategically positioning baffles can significantly improve separation efficiency.

3. How Does CFD Work in Analyzing Three-Phase Separators?

In conclusion, CFD allows for virtual testing of multiple designs, reducing the need for expensive and time-consuming physical prototypes. In addition, CFD helps to identify and mitigate issues such as foaming or emulsion formation by understanding fluid dynamics within the separator.

Author : Mr. Manish Bhasme | LinkedIn

Discover the expertise and services offered by CFD Consultants India, a trusted provider of Computational Fluid Dynamics (CFD) solutions in India.

Explore our journey in the cement industry, where we harnessed CFD simulations to overcome challenges and revolutionize production processes.

Discover the wide-ranging applications of Computational Fluid Dynamics (CFD) across industries such as aerospace, automotive, energy……….

Let's stay in touch!

To get recent updates, stay connect us on our LinkedIn page! Don’t hesitate to reach out to us for any questions, concerns or future collaborations

Contact Us

We are here to help! With just a quick input details we will be able to respond to your inquiry.

E-Mail: info(at)cfdconsultantsindia.com

CFD Consultants India a leading provider of CFD simulation consultation and services. We use finite volume computation technique to predict the flow behavior using various commercial CFD software’s. At CFD Consultants India, we understand the importance of accurate and reliable CFD simulations in the design and development process. With years of experience and expertise in the field, we offer customized solutions to meet your specific requirements and help you achieve your goals.

Whether you are looking to optimize your product design, improve performance, reduce costs, or enhance safety, CFD Consultants India can help. Contact us today to learn more about our services and how we can help you achieve your goals.

© Copyright CFD Consultants India 2023 | All rights reserved.